FOUNDRY & INVESTMENT CASTING

Over the past 35 years SOLAR IMPIANTI has designed and produced chamber and tunnel furnaces for de-waxing, sintering and pre-heating of moulds in precision casting during lost wax or thermoplastic resin casting processes.

Our technology is appreciated by leading Italian and international companies in the fields of industry, aeronautics and energy, even orthopaedics and art.

The furnaces are modular in structure and can be operated at temperatures of up to and over 1250°C, depending on the metal in use.

The following can be used for heating the shell molds, depending on requirements:

- Natural gas or LPG burners

- Recuperative burners

- Electric heating elements

HEAT TREATMENT

High and low temperature furnace for the heat treatment of metals and other materials, tailored to the customer’s specific needs.

Our many heat treatment processes exploit the effects of heat to modify and/or exalt certain structural, mechanical and technical properties of your chosen material.

SOLAR IMPIANTI offers heat treatment solutions for tempering, stress relieving, annealing, solution annealing, ageing, normalizing, drying, controlled air cooling, pre-heating for stamping and forging.

We develop fully automated plants with management and supervision systems for monitoring the entire process, combining high performance with treatment at the same high standard every time to guarantee the constant quality and durability of the product.

ENAMELLING, COATING & POLYMERISING

Solar Impianti offers enamel and varnishing factories a broad range of ovens and dryers differing in terms of application and the materials processed (sheet and other metal, glass, ceramics, MDF, etc.).

In the field of innovative heat treatment, we produce on demand advanced DRYERS WITH GAS-POWERED INFRARED RADIANT BURNERS for the following:

- Gelling, polymerising and firing of powder coatings

- Drying of wet-applied coatings

- Drying of porcelain enamels

- Drying after degreasing and washing the surfaces

- Pre-heating for degreasing and heat treatment in general

To see for yourself the great potential of Solar Impianti infrared panel heater we invite you to perform your test of treatment on the line in our factory.

CERAMIC & STONE

SOLAR IMPIANTI, established in 1984, has had technical expertise in the most important ceramics district in the world: Sassuolo. The company has developed upon its core business and gained many years’ experience in the production of kilns, dryers and complete plants.

The entire range of ceramic materials, from third-fire decoration, special articles and mosaics to single-fired tiles, double-firing, porcelain and extruded tiles, as well as tableware and gift and fancy goods, is produced worldwide in SOLAR GAS & ELECTRIC KILNS.

FOOD & VINEGAR

Love and passion for local tradition has motivated us to combine age-old methods with modern technology.

SOLAR MUST CONCENTRATION BOILERS for making traditional balsamic vinegar and dressings in Modena are just one example of this.

Our know-how in the field of industrial applications for infra-red emitter (both IR LAMPS or RADIANT BURNERS) has taught us how the technology is perfectly suited to ovens for cooking, grilling and dehydrating food.

- FOUNDRY & INVESTMENT CASTING

-

FOUNDRY & INVESTMENT CASTING

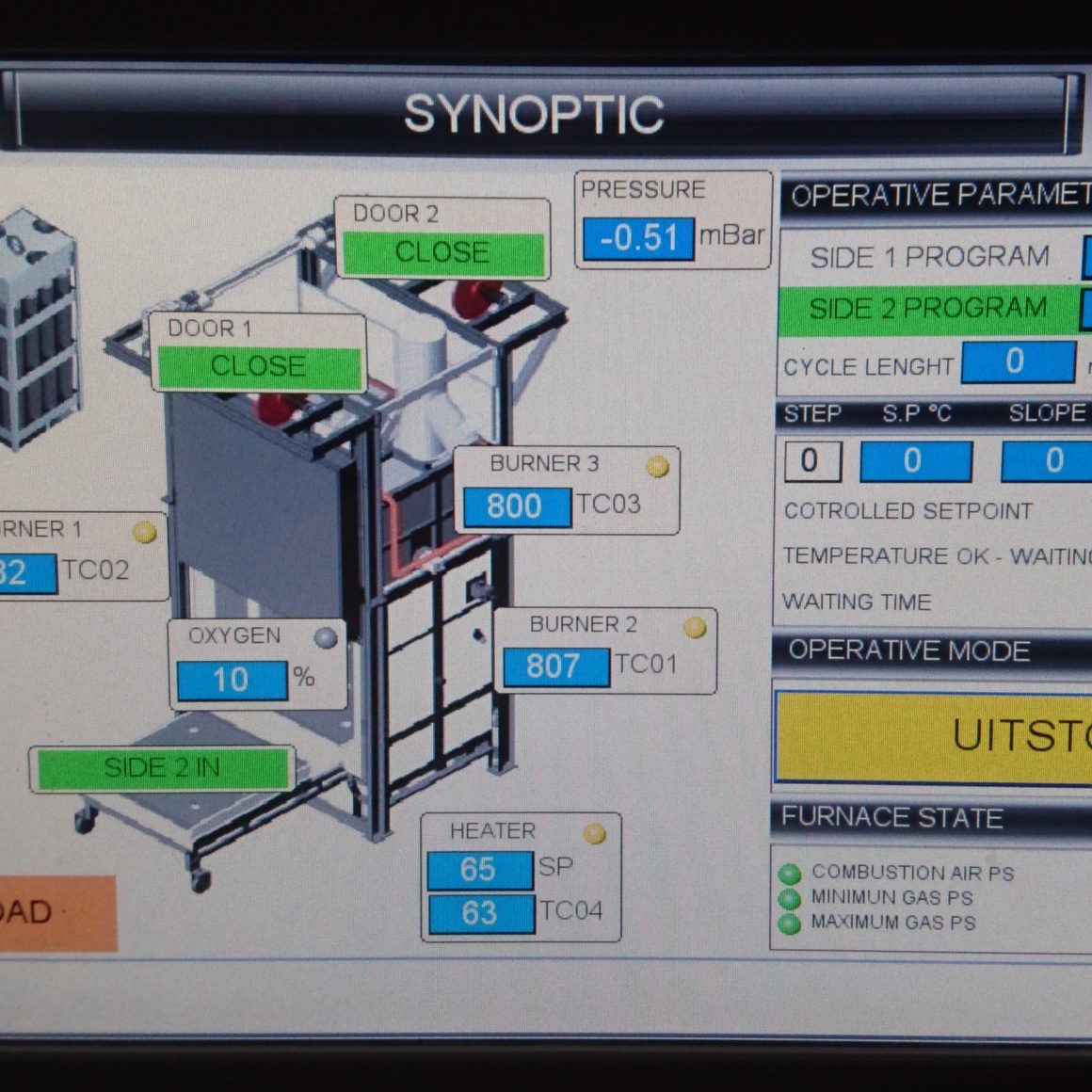

up to 1250°C and aboveOver the past 35 years SOLAR IMPIANTI has designed and produced chamber and tunnel furnaces for de-waxing, sintering and pre-heating of moulds in precision casting during lost wax or thermoplastic resin casting processes.

Our technology is appreciated by leading Italian and international companies in the fields of industry, aeronautics and energy, even orthopaedics and art.

The furnaces are modular in structure and can be operated at temperatures of up to and over 1250°C, depending on the metal in use.

The following can be used for heating the shell molds, depending on requirements:

- Natural gas or LPG burners

- Recuperative burners

- Electric heating elements

- HEAT TREATMENT

-

HEAT TREATMENT

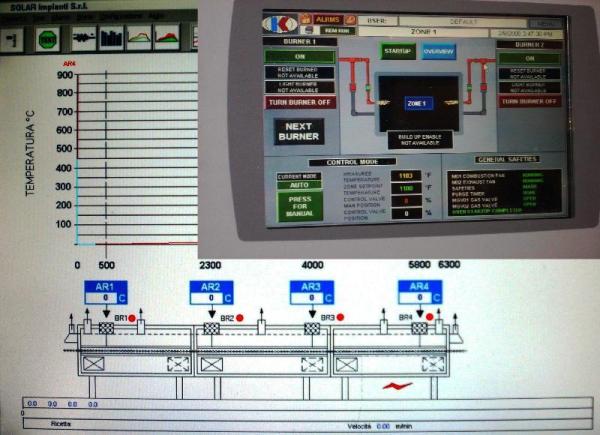

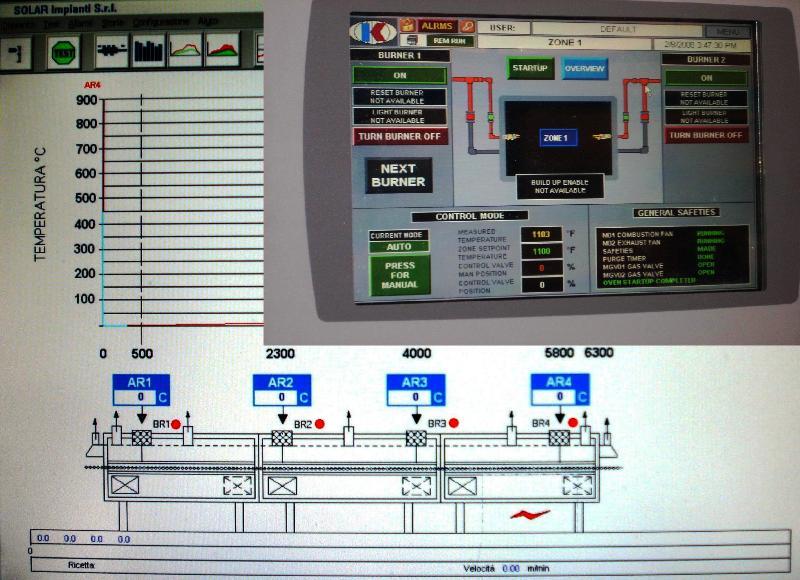

solutions for every needHigh and low temperature furnace for the heat treatment of metals and other materials, tailored to the customer’s specific needs.

Our many heat treatment processes exploit the effects of heat to modify and/or exalt certain structural, mechanical and technical properties of your chosen material.

SOLAR IMPIANTI offers heat treatment solutions for tempering, stress relieving, annealing, solution annealing, ageing, normalizing, drying, controlled air cooling, pre-heating for stamping and forging.

We develop fully automated plants with management and supervision systems for monitoring the entire process, combining high performance with treatment at the same high standard every time to guarantee the constant quality and durability of the product.

- ENAMELLING, COATING & POLYMERISING

-

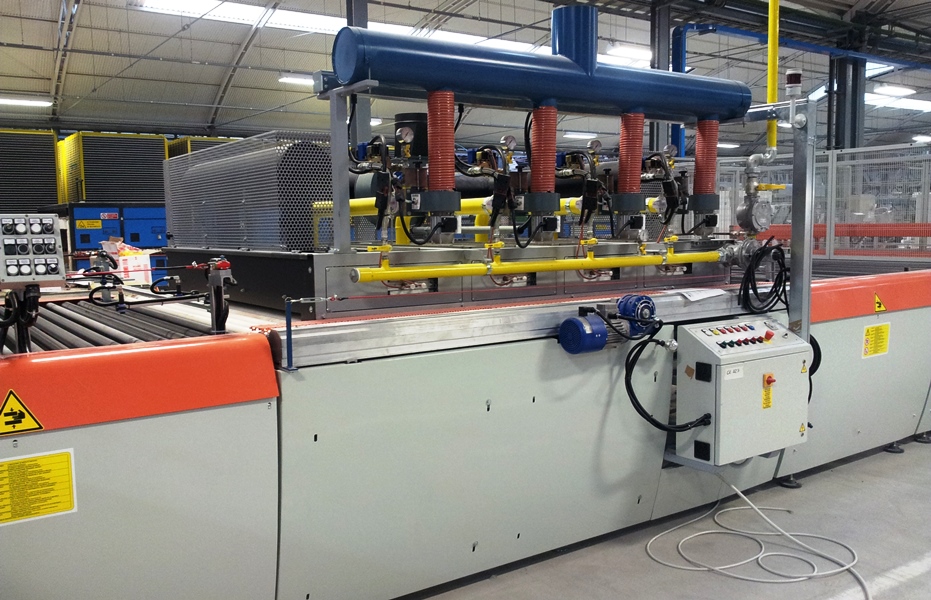

ENAMELLING, COATING & POLYMERISING

classic and IR treatmentsSolar Impianti offers enamel and varnishing factories a broad range of ovens and dryers differing in terms of application and the materials processed (sheet and other metal, glass, ceramics, MDF, etc.).

In the field of innovative heat treatment, we produce on demand advanced DRYERS WITH GAS-POWERED INFRARED RADIANT BURNERS for the following:

- Gelling, polymerising and firing of powder coatings

- Drying of wet-applied coatings

- Drying of porcelain enamels

- Drying after degreasing and washing the surfaces

- Pre-heating for degreasing and heat treatment in general

To see for yourself the great potential of Solar Impianti infrared panel heater we invite you to perform your test of treatment on the line in our factory.

- CERAMIC & STONE

-

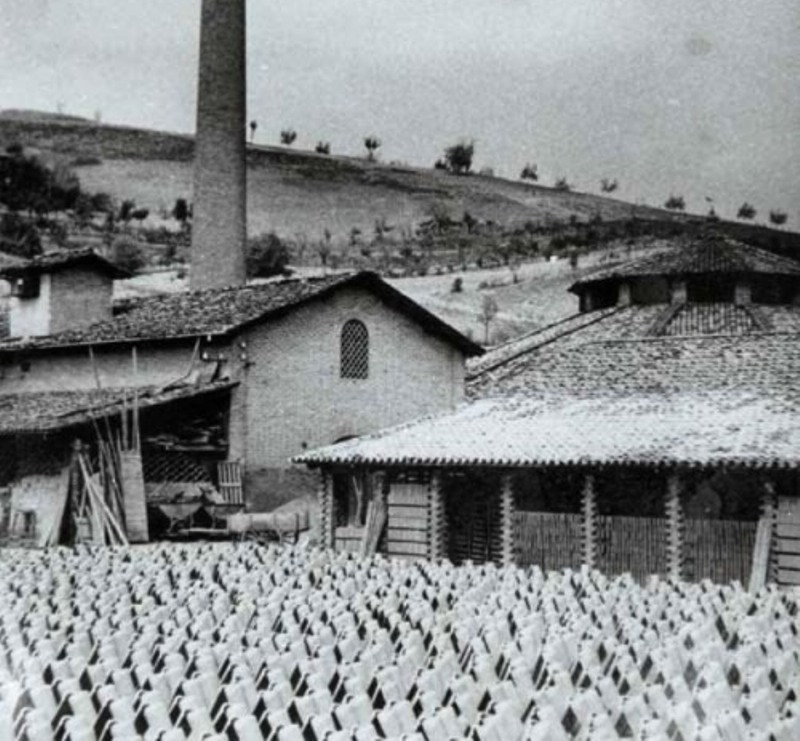

CERAMIC & STONE

the whole range of ceramic materialsSOLAR IMPIANTI, established in 1984, has had technical expertise in the most important ceramics district in the world: Sassuolo. The company has developed upon its core business and gained many years’ experience in the production of kilns, dryers and complete plants.

The entire range of ceramic materials, from third-fire decoration, special articles and mosaics to single-fired tiles, double-firing, porcelain and extruded tiles, as well as tableware and gift and fancy goods, is produced worldwide in SOLAR GAS & ELECTRIC KILNS.

- FOOD & VINEGAR

-

FOOD & VINEGAR

ancient rules and modern technologiesLove and passion for local tradition has motivated us to combine age-old methods with modern technology.

SOLAR MUST CONCENTRATION BOILERS for making traditional balsamic vinegar and dressings in Modena are just one example of this.

Our know-how in the field of industrial applications for infra-red emitter (both IR LAMPS or RADIANT BURNERS) has taught us how the technology is perfectly suited to ovens for cooking, grilling and dehydrating food.